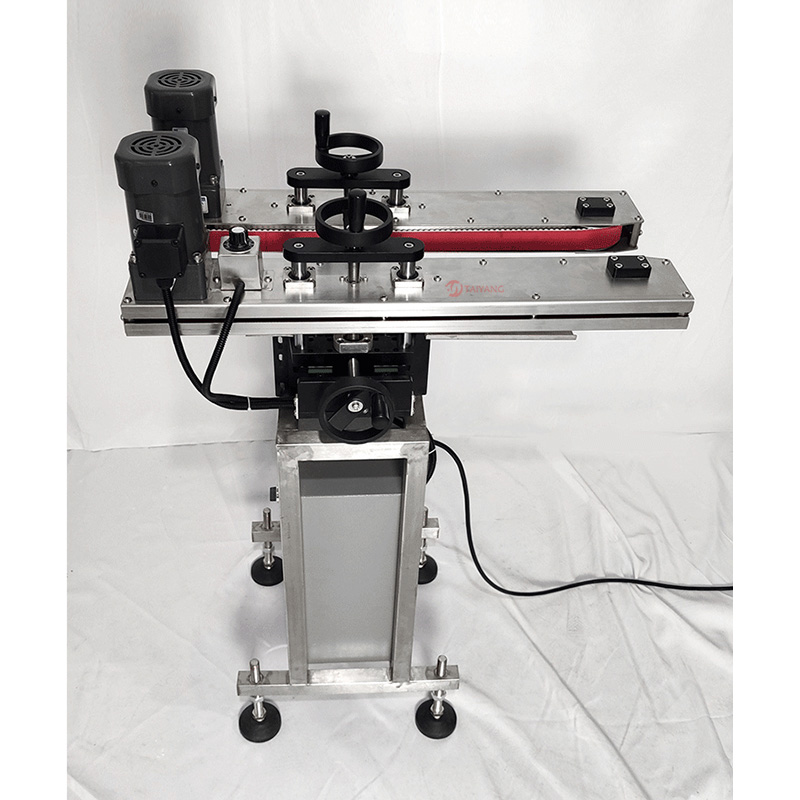

Has the Coding Bottle Clamping Transition Machine Been Unveiled?

2025-02-12

The unveiling of the Coding Bottle Clamping Transition Machine represents a significant milestone in the manufacturing industry. With its advanced technology and seamless integration of multiple functions, this machine is poised to transform bottling production and set a new benchmark for efficiency and safety. As the world watches, the bottling industry is poised to embrace this innovative solution and reap the benefits of automation and efficiency in production.

In a groundbreaking development within the manufacturing industry, a novel Coding Bottle Clamping Transition Machine has been introduced, marking a significant advancement in automation and efficiency. This innovative machine is designed to streamline the process of bottle clamping and coding, integrating multiple functions into a single, seamless operation.

The Coding Bottle Clamping Transition Machine combines advanced mold-transferring technology with coding and clamping mechanisms, ensuring precise and efficient handling of bottles during production. The machine is equipped with a support structure, a mold-transferring apparatus, a coding apparatus, and a clamping apparatus, all working in harmony to achieve optimal performance.

One of the key features of this machine is its ability to realize multiple mold-transferring processes within a basic mold, followed by subsequent coding and clamping. This combined mode of operation, utilizing cylinder direct-pushing, linear transmission, spring direction, shell positioning, and coding, ensures that bottles are accurately clamped and coded with minimal downtime.

Moreover, the machine primarily relies on compressed air as a power source, effectively eliminating the risk of security accidents caused by static electricity, friction, or other factors. This not only enhances the safety of the production environment but also contributes to the overall sustainability of the manufacturing process.

The introduction of the Coding Bottle Clamping Transition Machine is expected to revolutionize the bottling industry, significantly increasing production efficiency and reducing the potential for errors. With its ability to handle multiple bottles simultaneously and its integration of coding and clamping functions, this machine is poised to become a staple in bottling lines across the globe.

Industry experts have praised the innovation, noting that it addresses long-standing challenges in bottling production and sets a new standard for automation and efficiency. As the manufacturing industry continues to evolve, the Coding Bottle Clamping Transition Machine is expected to play a pivotal role in driving advancements and improvements in bottling processes.